Get more from LabVIEW and LabVIEW+

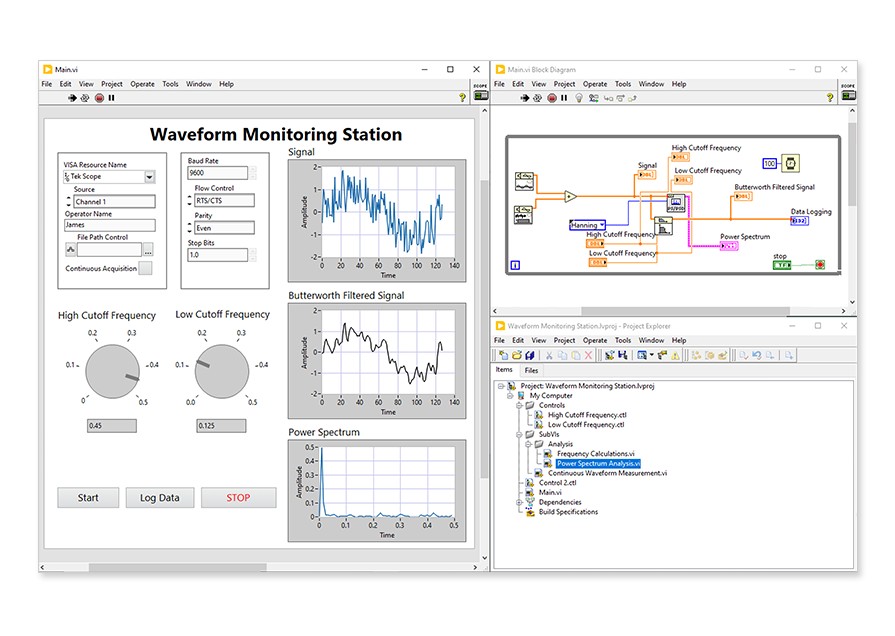

LabVIEW helps you work more quickly. Spend less time developing tests, automating instruments, analyzing data, and generating reports.

Featured Download

New FlexLogger Lite—Data in Minutes, Zero Coding

The new FlexLogger Lite edition is free companion software for NI data acquisition hardware. Quickly configure, log, and monitor mixed-signal systems with FlexLogger Lite—and upgrade anytime to the full-featured FlexLogger for more complex tasks such as automations, triggers, and alarms.

Elevate Performance with Test

Unlocking the full benefits of test isn’t just about using a better tool. It requires an intentional strategy with automation, standardization, and digital transformation initiatives.