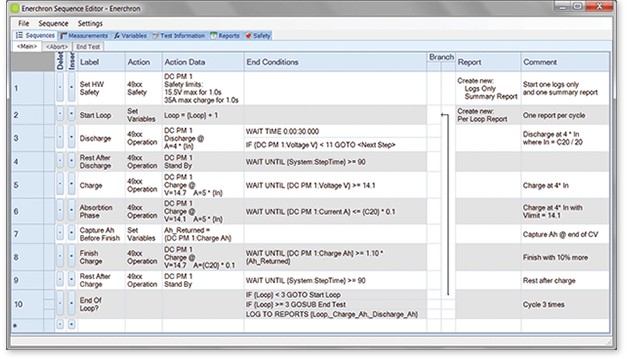

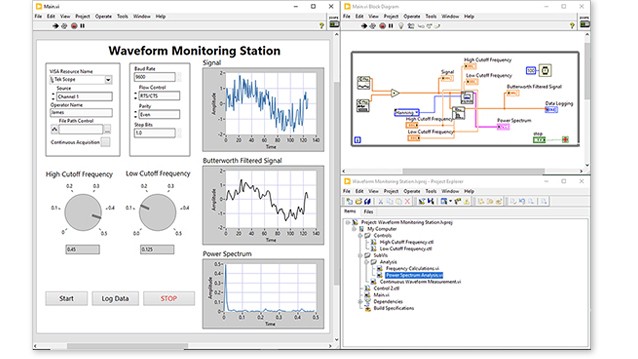

Enerchron is a powerful yet easy-to-use test executive created for battery testing to simplify and accelerate your test automation. A comprehensive battery test environment that includes integration with hardware and software tools, Enerchron is your shortest path to market.