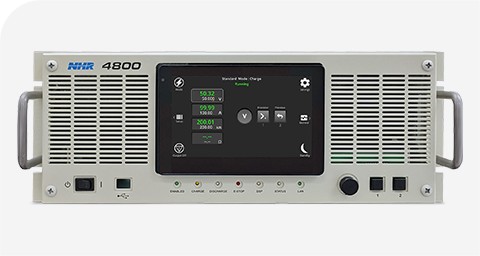

Meet Any Power Need for EV Testing

Electric Vehicle Battery test requires lots of power. From one battery pack to a full test facility, power requirements impact OpEx, CapEx, and CO₂ footprint, plus they can be a headache for lab managers who need to maximize utilization under strict safety conditions. Battery manufacturers and automakers thus require cost-effective, modular power that safely scales with their needs and helps them perform at their best despite shortened schedules and limited budgets.